An efficient material ordering process is essential for any roofing business. Inefficiencies can cause problems like incorrect pricing on estimates, wasted time, and disorganization, affecting job progress and profits.

AccuLynx roofing software integrates with the industry’s leading material suppliers–QXO, ABC, and SRS to make the ordering process faster and more efficient.

AccuLynx’s material supplier integrations help you:

- Create faster, more accurate estimates

- Save time placing orders

- Track material deliveries

- Improve organization and accessibility

- Predict future material needs

1. Create faster, more accurate estimates

Material prices change constantly, making it time-consuming for you to check supplier portals or place phone calls to update your pricing sheets. This process leaves you prone to inaccuracies when creating your roofing estimates.

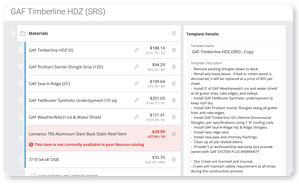

AccuLynx’s integrations directly connect to your supplier’s catalog, pulling your unique pricing and displaying real-time product availability. Utilizing estimating templates within AccuLynx is an effective way to leverage these supplier integrations and avoid errors. Right in your templates, material quantities and waste factors are automatically calculated to ensure accurate amounts are included in your estimate.

AccuLynx templates also store frequently ordered items, eliminating the need to repeatedly search the catalog. If a specific shingle color or product isn’t available, the template identifies this, so that you can suggest alternatives to homeowners immediately. This helps ensure your initial estimate is precise and reliable the first time.

2. Save time placing orders

Placing your orders over the phone or in person wastes time and can also lead to miscommunication and errors, about:

- Material quantity

- Shingle color

- Shingle style

Often, this may not be realized until the materials are delivered.

AccuLynx simplifies the process by allowing you to convert estimates into material orders with just a few clicks. These orders can then be directly submitted to your supplier through AccuLynx, eliminating the need for entering data twice and ensuring accuracy.

Additionally, orders are processed more quickly with AccuLynx’s material ordering integrations. Suppliers receive digital orders and can start processing them immediately, resulting in faster fulfillment and project timelines.

3. Track material deliveries

An inefficient ordering process may leave you wondering when materials are being delivered, or unable to make changes on the fly, which can lead to project delays.

AccuLynx’s Order Manager simplifies tracking material deliveries. When you place an order through AccuLynx, you receive key status updates about:

- Orders ready to be scheduled

- Shipping dates

- Delivery dates

- Order delays

The Order Manager provides real-time visibility into orders, allowing you to make informed decisions and adjustments as needed. You can monitor the progress of your material deliveries, anticipate any issues, and keep your projects on schedule.

Knowing this information is crucial because it helps you keep customers updated on project timelines and enables you to manage your crews more effectively. This process can be automated in AccuLynx, eliminating the need to manually update everyone involved.

4. Improve organization and accessibility

Not having a centralized place to store your material orders can leave you unorganized and limit future access to the information.

With AccuLynx material ordering, all of your material orders and details are stored in the job file, including:

- Order statuses

- Material quantities

- Costs

- Past orders on the job

This makes it easy to find the information you need. It can be particularly helpful if you are on a warranty or repair call and need to refer to past work. Having one source of truth that all team members can access ensures that everyone is on the same page.

5. Predict future material needs

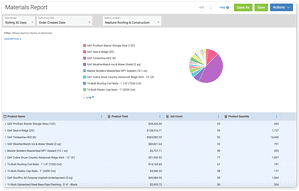

Accurate reporting is essential for understanding and anticipating your future material needs.

AccuLynx’s advanced reporting features allow you to track material usage and spending. For example, the pre-built Materials Report in AccuLynx enables you to run detailed analyses on the materials you have purchased, including:

- Types

- Quantities

- Colors

- Spend by supplier

This will help you better predict what future jobs will need and cost. It can also help you negotiate better pricing with your suppliers.

Frequently asked questions

How many estimating templates can I set up?

You can set up as many templates as you would like. AccuLynx trainers suggest having 2-3 templates for your most common orders in each trade you offer. Your AccuLynx trainer will help you set up the templates and get your account connected to QXO, SRS, or ABC.

How does pricing get updated and is it my specific pricing?

All materials displayed through the AccuLynx supplier integrations will automatically reflect your unique pricing. Pricing is updated daily to keep up with any changes or catalog additions.

How do I find the items I am typically ordering?

The best way to find an item is to use the item code listed on the supplier’s website or a previous invoice. You can find the item in AccuLynx by entering the code into the estimate template search bar.

How does the branch receive my orders? Will my usual rep get notified?

If you submit your order through the AccuLynx material supplier integrations, it will be automatically directed to the supplier’s system. The sales rep and branch manager will be notified of the order, as well as the distribution center for scheduling. If for some reason the branch can’t fulfill the order, they will reach out via phone or email to handle updates.

How do I get updates on my order?

When ordering through one of the three integrations, you will be able to track your order right from the Order Manager in AccuLynx. You can set a delivery date and be notified of any changes. You also receive documented proof of delivery in your AccuLynx job file.

Start using AccuLynx to order your materials

With AccuLynx’s material supplier integrations, you can create precise estimates, place orders swiftly, maintain organization, and forecast future needs accurately. Book a demo now to see how our supplier integrations can improve the efficiency of your business!